9 days in Japan- 6/23- 7/1/2024

Day 3-Sake Brewery tour-6/25/2024

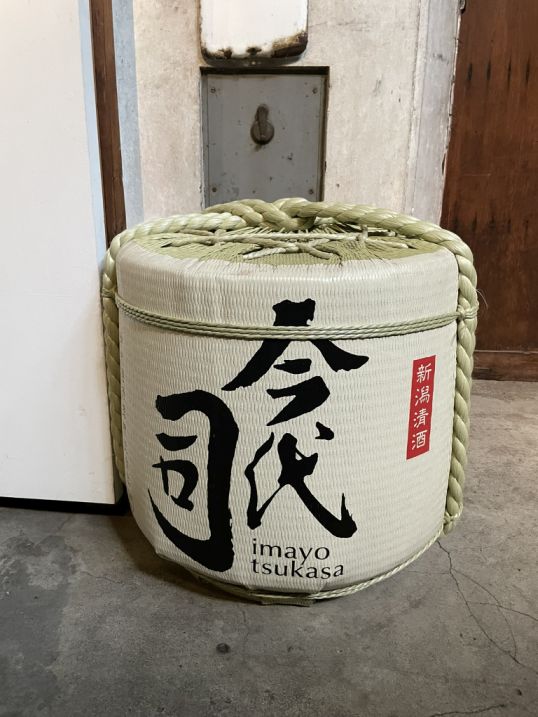

We reached Imayotsukasa Sake Brewery on foot, and from a distance it already felt different from the modern buildings around it.

The property was enclosed by tall white plaster walls, clean and bright, giving it the quiet dignity of an old estate. Behind the walls rose a large, traditional Japanese structure with dark wooden beams and gently sloping tiled roofs, simple and solid, built more for purpose than decoration.

The entrance was understated, marked by a wooden gate and a small sign bearing the brewery’s name.

There was no flashy storefront, just a calm, confident presence, as if the building itself was saying that it had been here for a long time and had nothing to prove.

We stepped inside and checked in for the tour.

We were then led into a large brewing room.

|

|

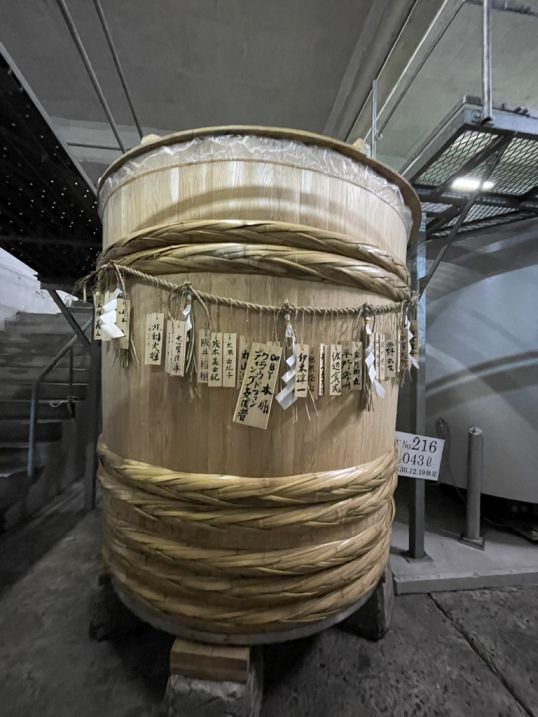

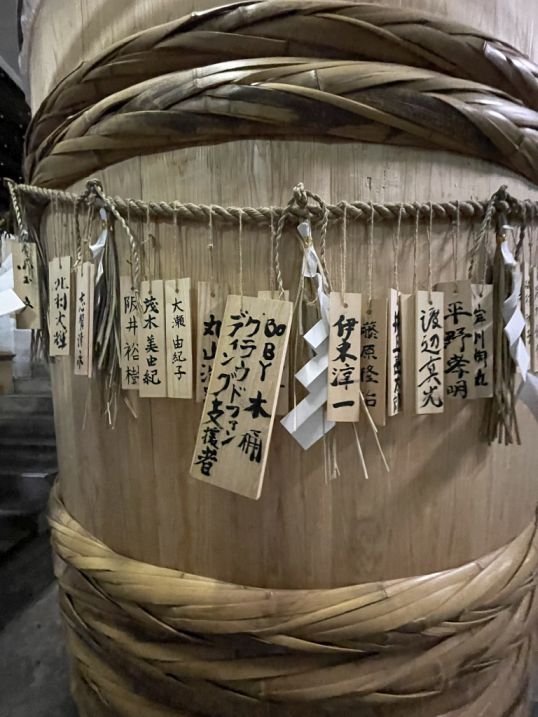

In the center stood an enormous wooden container, its surface marked with bold Japanese characters that looked hand-brushed and ceremonial. Nearby, along one side of the room, was a raised cement platform with a perfectly circular opening, covered by a thick wooden lid. It felt mysterious and ancient, like a quiet reminder of how sake had been made long before modern equipment existed.

|

|

Unfortunately, the tour itself was conducted entirely in Japanese, so we couldn’t understand most of what was being explained. Still, just being there was fascinating. The cool air, the smell of rice and fermentation, and the sight of these massive tools gave us a real sense of the craft and patience behind every bottle.

|

|

This straw ball is a sugidama, traditionally made from cedar branches (sometimes it looks like straw once dried), tightly bound into a large sphere and hung at the entrance of a sake brewery or inside important brewing rooms. When it is first made, it is bright green (Green sugidama → fresh sake has just been made). Over time, it slowly dries and turns brown (Brown sugidama → the sake has aged and matured). It is a symbol of new sake being brewed.

Our tour guide talked about the water in Niigata and people casually filling cups at the water dispenser.

|

|

Niigata is often called one of Japan’s best sake regions, and the main reason is its water. The water comes from heavy mountain snow in the Japanese Alps, natural filtration through layers of rock and soil, long, slow underground flow before reaching the city. This create water that is extremely pure, very soft (low in minerals) with a clean tasting. Soft water is ideal for sake because it allows slow, gentle fermentation, producing sake that is light, crisp, and elegant rather than heavy or harsh. This style is known as tanrei karakuchi, clean and dry which Niigata is famous for.

We were then led to a huge room with massive containers.

These massive wooden container are traditional sake fermentation and storage tanks, called kioke.

|

|

The containers are used to ferment steamed rice, water, yeast, and kōji mold, develop aroma and flavor, naturally regulate temperature. Cedar wood also subtly influences the sake, adding a faint, clean forest-like aroma.

Many modern breweries no longer use them daily, but keep them.

After the traditional wooden tanks, we were led into another space that felt completely different. Lined up in neat rows were tall gray containers, smooth and industrial, most likely made of stainless steel.

These are modern fermentation tanks that allow the brewers to control temperature to the exact degree, keep conditions sterile and consistent, monitor fermentation day and night, protect delicate aromas and flavors.

|

|

Beneath each one sat a small machine with a glowing light and a digital display quietly showing the temperature.

Sake fermentation is extremely sensitive. Even a few degrees can change how the yeast behaves, so these machines act like silent guardians, keeping everything perfectly balanced.

Farther into the room, we were led to a storage room with green containers.

These green containers are used as storage tanks for sake after fermentation. or containers used for blending, resting, or preparing sake before bottling.

These tanks may also be coated steel or insulated tanks designed to block light and heat, which can damage sake.

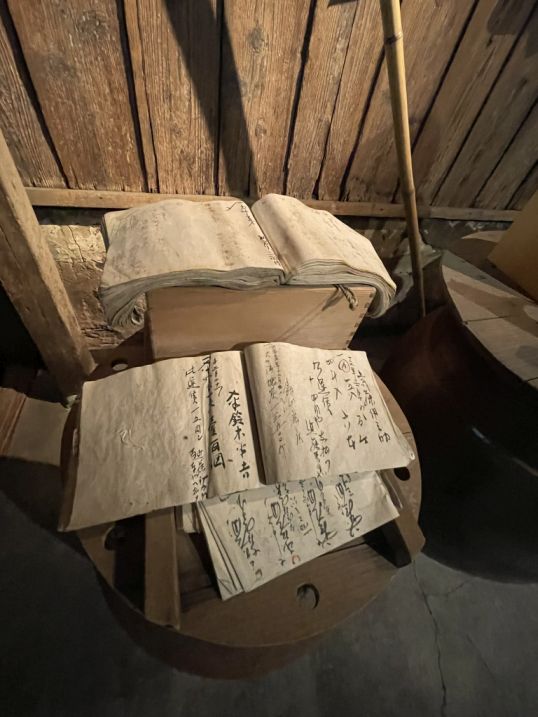

We were then led into a room dedicated to the brewery’s past, a quiet space filled with old marketing and advertising pieces from another era. The walls were lined with faded posters, all printed with bold Japanese characters and traditional designs. Large wooden and metal signs leaned against the walls, once meant to hang outside shops to announce fresh sake to the neighborhood.

|

|

Yellowed booklets, their paper softened by time. On the right, I think it is the company seal.

|

|

In one corner on display is a traditional navy-blue work clothes, dyed deep indigo and printed with crisp white Japanese lettering across the collard and the apron. These were the uniforms of the brewery workers, simple and practical, yet strikingly beautiful in their own way. Seeing them made the history feel personal, as if the people who brewed, carried, stamped, and sold the sake were still quietly present in the room.

|

|

A Kanzaze Vending Machine had been very popular in the 1960's to enjoy Kanzake (warm sake). These were standing at bars, and love by workers.

A display of all the bottles of Sake from this brewery.

|

|

This distiller is used to analyze the alcoholic content that is contained in Sake

|

|

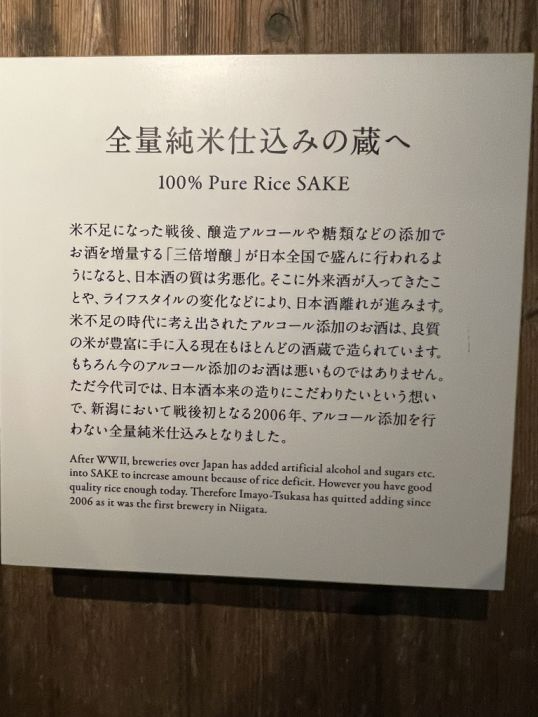

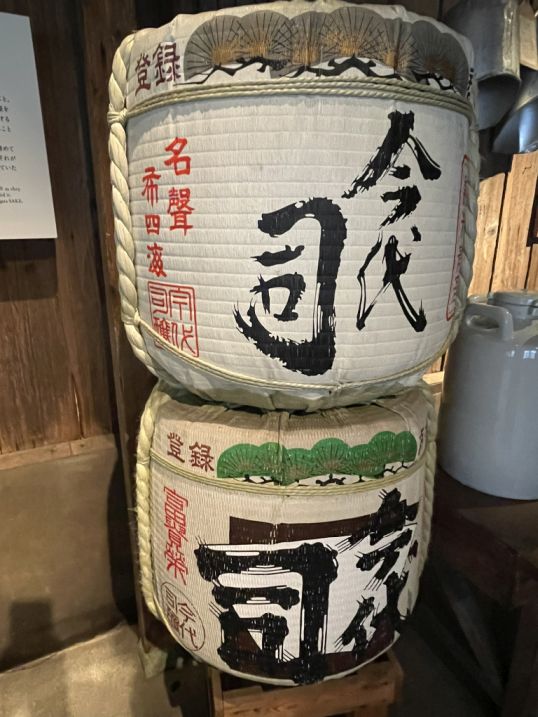

These large sake barrels are used mainly for decoration and display with beautifully lettered, they are called kazaridaru (decorative sake barrels). Traditionally they were used to store and transport sake, and the bold calligraphy shows the brewery name and brand.

These are classics small white cups with blue indigo circles at the bottom. On the left are the small flat sake plates called sakazuke used in ceremonies and formal drinking.

The wooden sake box/tray is a masu, a square wooden cup traditionally made of cedar, sometimes used to serve sake or to measure rice.

|

|

Warming cask are originally made of wood, but today, it is made of ceramic or metal.

|

|

At the end of the tour, the guide brought us back to the room with the modern green tanks and pointed to a sheet listing their different sake varieties. Even though we could not understand the explanation, it felt like a quiet introduction to everything they had just shown us, water, rice, time, and patience, all turned into bottles.

Finally, we were led into the tasting room.

Tasting menu.

|

|

The tasting room was lined with rows of sake bottles, each one different in shape, label, and color. Some were simple and modern, others decorated with elegant calligraphy or soft illustrations, hinting at the character of what was inside.

|

|

Tasting the Koi-labeled bottle, which we learned was their premium brew, proudly displayed among the others.

Standing there, surrounded by so many choices, it finally became clear just how deep and varied the world of sake really is.

This cloudy sake is called nigori-zake which is coarsely filtered, so some of the rice solids remain in the liquid. That’s why it looks milky or cloudy instead of clear. The taste is slightly sweet. It’s often served at tastings because it’s easy to enjoy, even for people new to sake.

Hoa checking the different type of sake.

These 2 guys were part of the tour, Cheers!

Afterwards, we were led into the store where people can buy all their products.

Sake available for sale.

Display in the store.

This area is for their expensive sake.

Our visit to Imayotsukasa Brewery was both fascinating and quietly beautiful. From the traditional white-walled exterior to the cool, fragrant brewing rooms inside, we were able to see how centuries of craftsmanship and modern precision come together in every bottle of sake. Even though the tour was in Japanese, walking among the massive wooden barrels, temperature-controlled tanks, historic tools, and old advertising displays gave us a deep appreciation for the care and patience behind the process.

Ending in the tasting room, surrounded by rows of beautifully labeled bottles and sampling a lot of the sake, felt like the perfect final touch. It was a calm, thoughtful experience that revealed not just how sake is made, but how closely it is tied to Niigata’s pure water, its rice culture, and its quiet dedication to tradition.

NEXT... Day 3- Lunch and Dinner